what are motor pumps?

Motor pumps play a very important role in the field of engineering and in the global energy ecosystem. This is because motors convert electrical energy into mechanical energy. This mechanical energy is used for different purposes, such as water pumping, wastewater treatment, air pollution control and many more. In the case of agriculture, the most common use of motor pumps is the irrigation of crops, both in small orchards and in large extensions of land.

Types of motor pumps

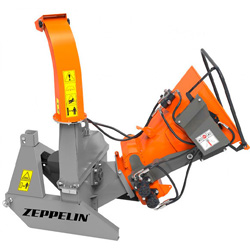

There are several types of motor pumps, including submersible, canned and magnetic drive motors. There are also motor pumps for tractors. Each of these types has its own function in different sectors, from agriculture and construction to cleaning structures or draining flooded areas. Here is a brief description of the functionality of each type.

Submersible motor pumps

Submersible motor pumps offer a number of advantages over their surface mounted counterparts. They can operate in places where surface-mounted pumps cannot, and they can fit into tight spaces. In addition, they operate almost silently, although you will need to check them from time to time to make sure they are still working properly.

These motors have rugged construction and secure sealing to protect them from water damage. This allows them to last for years when used in conjunction with pumping equipment. In addition, they have a number of safety features that ensure their safe operation in submersible environments. A submersible motor pump is a good choice for marine applications.

Submersible motor pumps can be used to pump large volumes of clear water. They can be used to pump sewage, rainwater and water from various reservoirs. They can also be used to pump water from homes and businesses. Submersible pumps can be connected to horizontal or vertical pipes. However, they cannot be tilted.

Canned motor pumps

Canned motor pumps are a great solution to liquid transfer problems. Their double containment system means that the liquid will not escape if the pump breaks down. In addition, the motor and stator are protected from pressure. Canned motor pumps are also less expensive than magnetic drive pumps, which are expensive and difficult to maintain.

When using canned motor pumps, make sure that the liquid is pumped in the correct direction. Check the discharge head to make sure it is at the desired level and restart the pump. If it is not, you should adjust the motor or piping system specifications.

Magnetic drive motors

Magnetic drive motors for motor pumps operate by using a magnetic field to move the pump. High-strength permanent magnets are embedded around the pump impeller hub. The magnets are connected to the motor through a thin coating that seals the internal parts. A small clearance is left around the impeller, which rides on an internal shaft and bushing assembly. Magnetic drive motor pumps have the advantage of using minimal oil to operate, and are lightweight and durable.

Magnetic drive motors are leak-proof. Since there is no direct contact between the pump impeller and the electric motor, there is no risk of leakage. This means that there will be no leakage of hazardous chemicals into the pump, and the power of the motor is effectively transferred to the liquid. Magnetic drive motors also require less maintenance, thanks to their simple design.

PD pumps

Partial discharge (PD) activity in industrial pump motors is caused by several factors. The main contributing factor is the amount of electrical voltage applied to the motor insulation. As a result, PD can cause progressive breakdown of the insulation over time. PD measurements are therefore crucial to motor reliability. These measurements can help ensure that motor pumps operate efficiently even when the insulation condition is poor.

Positive displacement pumps are widely used in a variety of industries and applications. The advantages of this type of pump over other types of pumps are numerous, but there are some differences between the two. Some positive displacement pumps are ideal for hazardous environments, while others are better suited for less abrasive liquids.

Recommendation from Intermaquinas: Motor pumps Anova

Motor pumps Anova are available in several models. They are available with electric or battery drives, with long cutting lengths and good autonomy. In addition, each model features a powerful motor and a durable design that will last for many years. The brand is considered one of the best on the market, with a great quality/price ratio.