2T oil mix 1 liter Anova

- Size: 1 liter

- Base: Synthetic

- Designed for agricultural machinery engines with a 50:1 mix

€20.46 VAT incl.

The gasoline hedge trimmer Oleo Mac HC 246 P is powered by a 2-stroke Emak EURO engine. It provides a power of 1.5 HP / 0.77 kW and a displacement of 21.7 cc.

This model also has a minimum engine speed of 3100±100rpm and a maximum idle speed of 10200±200rpm. It has an hourly fuel consumption at maximum power of 380 rpm.

The gasoline hedge trimmer Oleo Mac HC 246 P has a digital electronic ignition system . It has an 11000 rpm limiter and a NGK CMR7H spark plug. It also offers a transmission system with a 0.245 kinematic group and a centrifugal clutch with 4100rpm engagement.

The gasoline hedge trimmer Oleo Mac HC 246 P has a feed and lubrication system with Walbro WT-1223 carburetor and Mix fuel 4% (25:1) - with PROSINT oil 2% (50:1). It also has a capacity of 0.5 L, a primer and a paper air filter.

This hedge trimmer guarantees good safety. It has a sound pressure of 98.8 dB(A) and a sound power of 108 dB(A). It has a vibration level Front 6.6 m/s2 Rear 8.6 m/s2.

The tool Oleo Mac HC 246 P offers good ergonomics. It includes two front mitten-circular handles and a 180° rotating rear handle.

The hedge trimmer Oleo Mac HC 246 P has a cutting system with a blade length of 600mm. In addition to a blade pitch of 30 mm. This model has a weight of only 5.2 kg.

| Engine | 2-stroke Emak EURO 1 |

| Power | 1.5 HP / 0.77 kW |

| Displacement | 21,7 cc |

| Minimum engine speed | 3100 ± 100 rpm |

| Maximum idle speed | 10200 ± 200 rpm |

| Hourly fuel consumption | 380 rpm |

| Spark plug | NGK CMR7H |

| Transmission | 0.245 kinematic group |

| Clutch | Centrifugal with engagement at 4100 rpm. |

| Carburetor | Walbro WT-1223 |

| Capacity | 0,5 L |

| Acoustic pressure | 98.8 dB(A) |

| Acoustic power | 108 dB(A) |

| Vibration level | Front 6.6 m/s2 Rear 8.6 m/s2 |

| Front Handle | Circular-Handle |

| Rotating Handle | 180° rotatable |

| Blade length | 600 mm |

| Blade pitch | 35 mm |

| Weight | 5,2 Kg |

|

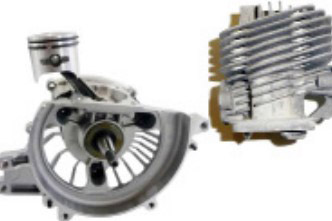

Piston with two rings, shaft and connecting rod in forged and machined steel, roller cages and cylinders coated with nickel, to ensure long-term efficiency even in the face of intensive use. |

|

High-quality steel blades with cutting edges on top. These ensure a clean and precise cut that does not damage the branch. Adjustable blades to adapt to any type of plant. |

|

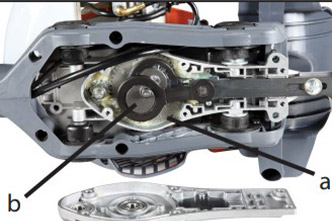

Professional gearbox, made of aluminum (a), with pinion in bearings and connecting rods with rollers (b). This is to guarantee a long service life, low noise level and low vibrations. |

|

180° rotating handle (only on double-blade models). The handle ensures a comfortable and secure grip even when using the machine for side cuts. |

|

Paper filter, for increased filtering capacity and motor longevity. |

|

Anti-vibration system, consisting of 4 shock-absorbing springs, placed between the movement box and the handles, which reduces stress for the user. |

|

The nylon mixing tank complies with the strictest safety standards, thanks to its transparency, allowing immediate control of the fuel level. |

|

Easy maintenance: a screw cap allows access to clean the paper filter with air, while another cap allows access to the starter housing and the muffler. |

| IMPORTANT It is mandatory for the customer to check oil and grease levels before start-up ! |

| If it is not possible to check the goods at the time of receipt, it must be indicated on the carrier's sheet that the customer is in agreement unless an examination is pending. |

Data sheet

Specific References

At Intermaquinas, we make sure that your agricultural machinery always works at 100%. We offer a complete after-sales service that covers any possible incident with your equipment.

Whenever there is a warranty or factory defect, your machine will be covered: 1 year for professionals and 2-3 years for individuals. We take care of everything: we or the carrier will pick up the machinery and send it to the factory for repair or, if necessary, replacement.

To solve minor problems in the most agile way, we have our online mechanics service. Our specialized mechanics will guide you step by step over the phone to solve the breakdown quickly and easily, avoiding unnecessary trips. Intermaquinas recommends greasing after each operation to ensure perfect performance and extend the life of the machines.

If the problem is more complex or cannot be solved with telephone assistance, we take care of everything. We pick up your machine and take it to our workshop, where our specialized mechanics will repair it, whether it is light or heavy machinery. We know that many technical services are far away and that a van is not always available for transport. Carrying it by car can be uncomfortable, as well as entailing the risk of scratches or dirt. Therefore, with our pick-up service you save time and complications, ensuring that your equipment arrives in perfect condition for repair.

Our team of specialists is available to ensure that your machinery is always in the best condition. Contact us and we will help you with the fastest and most effective solution.

- Battery, charger and heads not included

| get the KIT battery + charger and save 98,94 €! |