Liquid Extractor-Injector Kit Anova

- Liquid extractor-injector kit Anova

€33.20 VAT incl.

The Brushcutting robot Agria RS9500-70 offers total control in the hands of the operator, ensuring precise and efficient handling. Its excellent finish of mulching cut and robust, hardened steel shredding blades ensure optimum clearing performance.

The versatility from Agria RS9500-70 is evidenced by its ability to adapt to rugged terrain, thanks to its tracked that provide exceptional traction. Its design with low center of gravity and in the center of the machine provides stability, even on steep slopes.

In addition, the security is a priority, with features such as protection against thrown objects, safety switches and emergency shutdown the system is equipped with an automatic shutdown system in case of loss of the remote control signal.

This brushcutting robot is also distinguished by its low voltage of 48 V, providing an additional layer of security. The electromechanical brake ensures safe transport, and the operator's manual is always within reach thanks to the integrated QR code. With the Agria RS9500-70, efficiency, safety and comfort come together to deliver an exceptional brushcutting experience.

|

Robust shredding blades

The toothed shredder blades are manufactured in mild steel and hardened. |

Electrical cutting height

The remotely controlled electric height adjustment allows the cutting height to be varied between 30 and 130 mm, the display of the control is visible on the control screen. |

Safe loading

The device includes four cast bolts which facilitate the secure attachment of lashing hooks during transport. |

|

Easy transport

Your compact design not only facilitates transportation with small vehicles, but also optimizes mobility and versatility in different environments. |

Removable and quick-release fuel tank

The quick-removable fuel tank simplifies and accelerates the process refueling even in difficult terrain, using standard 5-liter drums. |

Automatic tensioning of the

Thanks to the automatic V-belt tensioner, there is no need to adjust the belt tension manually, as the belt tensioning is done manually automatically. |

| Motor model | Briggs & Stratton Vanguard |

| Motor type | 1-cylinder and 4-stroke |

| Power | 11.9 kW (16.2 hp) |

| Torsional stress | 30.6 Nm at 2400 rpm |

| Fuel system | 2 x 5 liters; removable fuel tanks of 2 x 5 liters; removable fuel tanks of Agria |

| Speeds | Selectable 3 speed ranges |

| Speed range 1 | 0 - 2 km/h |

| Speed range 2 | 0 - 3.8 km/h |

| Speed range 3 | 0 - 5.8 km/h |

| Brake | Fail-safe electromechanical brakes |

| Slope capacity | 45° (100%) |

| Type of cut | Rotary shredder for tall grass |

| Blade type | 1 Shredding blade |

| Equipment drive | Belt drive with electromagnetic clutch |

| Working width | 70 cm |

| Cutting height | 30 - 130 mm, adjustable by remote control |

| Performance | max. 2,500 m²/h (5 km/h) |

| Remote control | Autec-Safety RC-System with 2,8" display |

| Max. working range | max. 300 meters |

| Recommended working range | max. 100 meters |

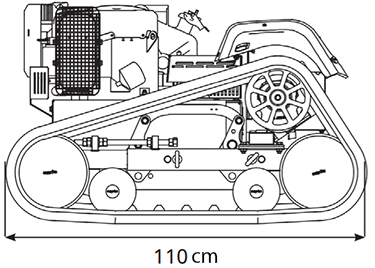

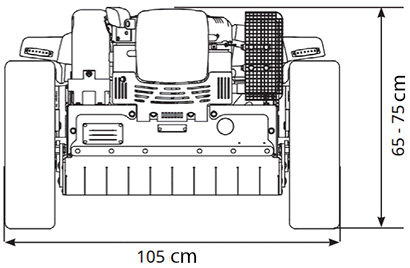

| Dimensions L x W x H | 110 x 105 x 65 - 75 cm |

| Ground pressure | 0.08 kg/cm² (0.08 kg/cm²) |

| Weight (with full drums) | 344 kg |

|

|

| IMPORTANT NOTICE |

| Mandatory on the part of the customer, review oil and grease levels prior to start-up. If it is not possible to check the goods at the time of receipt, it must be indicated on the carrier's sheet that the customer is in agreement except for pending examination. |

Data sheet

Specific References

At Intermaquinas, we make sure that your agricultural machinery always works at 100%. We offer a complete after-sales service that covers any possible incident with your equipment.

Whenever there is a warranty or factory defect, your machine will be covered: 1 year for professionals and 2-3 years for individuals. We take care of everything: we or the carrier will pick up the machinery and send it to the factory for repair or, if necessary, replacement.

To solve minor problems in the most agile way, we have our online mechanics service. Our specialized mechanics will guide you step by step over the phone to solve the breakdown quickly and easily, avoiding unnecessary trips. Intermaquinas recommends greasing after each operation to ensure perfect performance and extend the life of the machines.

If the problem is more complex or cannot be solved with telephone assistance, we take care of everything. We pick up your machine and take it to our workshop, where our specialized mechanics will repair it, whether it is light or heavy machinery. We know that many technical services are far away and that a van is not always available for transport. Carrying it by car can be uncomfortable, as well as entailing the risk of scratches or dirt. Therefore, with our pick-up service you save time and complications, ensuring that your equipment arrives in perfect condition for repair.

Our team of specialists is available to ensure that your machinery is always in the best condition. Contact us and we will help you with the fastest and most effective solution.

- Heads and batteries not included as standard